Cleaning Up Your Act: Sustainability in the Artists’ Studio

2024 Mar 12th

Every day, we hear talk of sustainability. Sadly, as we all know, there are a lot of products used regularly in the visual arts, that are not very friendly to the environment. Whether we look at toxins in solvents and grounds, plastics in paint, or the heavy water usage and destruction of forests that play a part in traditional western-style papermaking, making sustainably-made Japanese papers available to inspire and encourage creativity and artistic practice, are founding principles of The Japanese Paper Place.

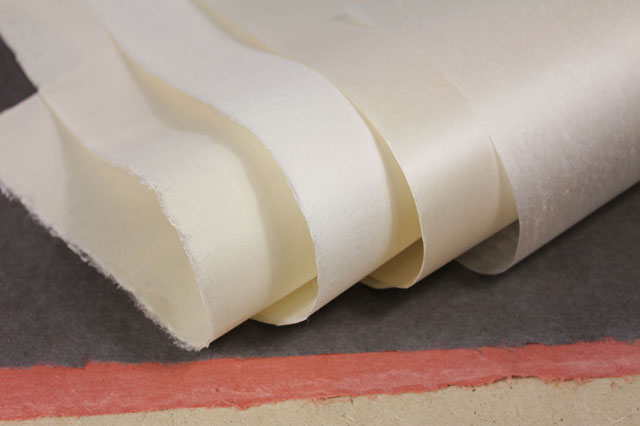

Heritage Washi made from different fibres

Many artists and businesses are making conscious efforts to the reduce their impact on the environment. When it comes to sustainability and paper, handmade washi, especially Heritage Washi, is your best choice. Heritage Washi is a term coined by The Japanese Paper Place to describe papers that are still handmade by skilled artisans in Japan using heritage methods. Generations of papermakers often live and work in the same village and use the same studio as their forebears.

Mino washi papermaker forming a sheet

Japanese-style papermaking relies primarily on cultivated crops of kozo and mitsumata. The same field of kozo can supply a papermaker with fibre for up to 50 years before it needs to be replanted. Although slower growing, mitsumata is much the same. Healthy human bodies to carry out the manual harvest and processing of the fibre, fresh running water, sunlight, and clean snowfalls, are the key elements to making washi.

Kozo field in August

The growth period for kozo is one year. Kozo fibres are harvested by hand, cooked with soda ash to aid the softening process, and lightened either in sunshine and fresh running water, or are laid on the snow in open fields. No harsh or caustic additives or bleaches are used. As a result, the overall longevity, quality – crispness, tone, surface beauty – and sustainability are unparalleled.

Mitsumata field in spring

While mitsumata needs three years of growth before it is ready to harvest, the same care and assiduousness go into processing mitsumata fibre and forming it into sheets of paper. Mitsumata fibre is shorter, and softer than kozo and yields a warmly-toned, elegant paper. These factors, as well and the longer growing period add to the cost of mitsumata washi.

Japanese Gampi

Japanese gampi is not a cultivated crop but grows in the wild on select mountains. As you can imagine, the care and harvesting of gampi is an arduous task. A lack of labourers and the effects of the climate crisis have impacted the gampi harvest. As a result, Japanese-grown gampi is becoming increasingly difficult to come by. In recent years, papermakers have turned to China to procure gampi fibre as it is more readily available and less costly. The resulting paper is of fine quality, but it is not considered Heritage Washi and the ongoing availability of gampi fibre paper is currently in question.

Kizuki Somegami is made from 100% Chinese kozo

Gampi Itaboshi is made from 100% Chinese gampi

Agricultural practices and the environmental impact of growing salago (Philippine gampi), Thai kozo, or Chinese fibres are not well-enough known to us to speak to the sustainability of products made with these fibres. However, the process of creating paper from these fibres is still less-damaging to the environment than Western-style pulp- or rag-based, machine-made papers. Both of these Western methods, which demand the use of high volumes of water, and caustic ingredients to aid in the processing of the fibre, often employ chemical bleaching to achieve the bright whiteness that is familiar to us. For artists looking to increase the sustainability of their practice, handmade Japanese paper is an easy choice.

If you have any questions about our products, please contact us. We are always happy to help you to make sustainable choices.